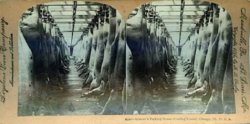

Meat packing industry early 1900s

The Armour & Company meat packing plant in National City, Illinois is a window into a bygone era, a time capsule with late-19th century technology still on display. During its heyday the busy stock yards of East St. Louis were the largest in the world, and known around the U.S. as the “Hog Capital of the Nation.”

The Armour & Company meat packing plant in National City, Illinois is a window into a bygone era, a time capsule with late-19th century technology still on display. During its heyday the busy stock yards of East St. Louis were the largest in the world, and known around the U.S. as the “Hog Capital of the Nation.”

Advances in technology and labor disputes ultimately drove the meat packers out of National City. The obsolete Armour plant had become expensive to operate and was eventually shut down by the company in 1959.

Unused since Armour & Co. left nearly 55 years ago, the 110 year-old structure still sits in East St. Louis today.

*

*

Armour & Company

Founded by the Armour brothers in 1867, Chicago-based Armour & Company was a meatpacking corporation led by Philip Armour (left). A robber baron industrialist, Philip is also remembered for his contributions toward innovations in the meat industry.

In the 19th century the lack of refrigeration technology dictated the process for meat packing and distribution; without it, the meats needed to be consumed quickly or preserved with salt.

With time at a premium, Philip revolutionized meat processing by centralizing operations next to rail yards.

With time at a premium, Philip revolutionized meat processing by centralizing operations next to rail yards.

Several hundred miles to the South of Chicago, an industrial district just outside St. Louis was established in 1873. The East St. Louis National Stock Yards would employ the centralized delivery and distribution concept in the district via rail.

In 1907, East St. Louis’ National Stock Yards were incorporated as the National City Stock Yards. This allowed city officials to offer more favorable regulations and tax climes in an attempt to attract major industry.

The National City Stock Yards encompassed 650 acres and at its peak was capable of processing 30, 000 cattle, 50, 000 hogs, and 20, 000 sheep daily.

The National City Stock Yards encompassed 650 acres and at its peak was capable of processing 30, 000 cattle, 50, 000 hogs, and 20, 000 sheep daily.

Until World War II, National City’s stock yards were the largest horse and mule market in the world.

Refrigeration Era

In the 19th century, meat processing was largely disorganized and inefficient. Fresh beef could only be shipped short distances before it would spoil.

Local butchers operated independently of the packing houses, which often were separate entities from the slaughter houses.

Given the many different layers of processing, access to fresh packaged meats was limited to select larger city centers. The lack of refrigeration required each major city to have its own stockyard, packing house, and distributor, increasing costs to the meat industry.

Before centralization, transport costs by rail were higher as the entire cow had to be transported rather than just the sale-able beef. At the time, more than half of a butchered cow was considered waste.